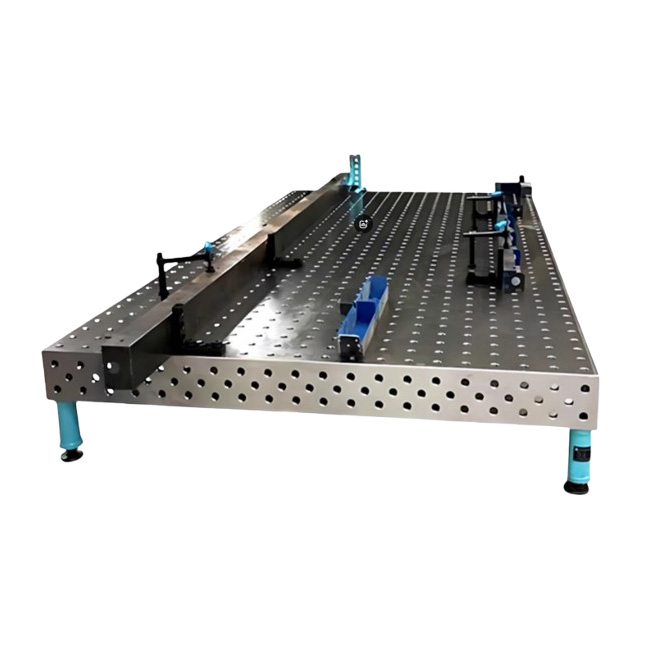

Three-Dimensional Flexible Welding Platform

The Three-Dimensional Flexible Welding Platform is an advanced modular fixturing system designed for high-precision welding, assembly, and fabrication. Its grid-based surface and standardized boreholes allow for rapid positioning and secure...

The Three-Dimensional Flexible Welding Platform is an advanced modular fixturing system designed for high-precision welding, assembly, and fabrication. Its grid-based surface and standardized boreholes allow for rapid positioning and secure clamping of workpieces of varying shapes and sizes. This system is ideal for repetitive and custom projects, offering unmatched flexibility, efficiency, and accuracy in industrial welding environments.

Product Features:

High Flatness and Rigidity:

Manufactured from high-quality cast iron or nitrided steel (e.g., Q345 or 42CrMo), with a surface hardness up to HRC 45-60, ensuring excellent wear resistance and long-term accuracy.Modular Hole Grid System:

Standard hole diameter (usually Ø16 mm, Ø22 mm, Ø28 mm, or Ø50 mm) with evenly spaced 3D grid pattern (e.g., 100×100 mm), compatible with a complete range of positioning and clamping tools.5-Sided Accessibility:

Working surface and side faces all contain precision holes, enabling multi-angle fixturing and true three-dimensional workpiece positioning.Flexible Fixturing:

Supports fast assembly and reconfiguration with modular locator pins, clamps, support arms, V-blocks, angle brackets, and custom jigs. No need for complex custom fixtures for every new job.Corrosion-Resistant Finish:

Options include black oxide, plasma nitriding, or other anti-rust treatments to withstand heavy-duty shop conditions.Load Capacity:

Built to carry loads up to several tons, depending on table size and thickness. Ideal for handling large or heavy steel structures.

Standard Sizes (Custom Sizes Available):

1000×1000 mm

1200×1200 mm

1500×1000 mm

2000×1000 mm

2400×1200 mm

3000×1500 mm

(Custom dimensions, hole spacing, and material configurations can be made to order.)

Applications:

Precision welding and assembly of frames, cabinets, and enclosures

Fabrication of automotive and aerospace components

Robotic welding system integration

Heavy steel structure and machinery assembly

Custom metal part prototyping

Advantages:

Fast Setup & High Repeatability: Reduce production time by up to 60%

Tool-Free Adjustment: Easy to reconfigure for different projects

High Precision Welding: Achieve tight tolerances and consistent quality

Cost-Effective: Reusable tools eliminate the need for custom jigs

Versatile: One platform fits thousands of applications

Optional Accessories:

Clamps, angle stops, locator pins, support legs, height adjusters, extension blocks, and more.

Contact Us:

Looking for a tailored solution? We offer full OEM/ODM customization for your welding table system. Reach out today for a quotation or CAD drawing!