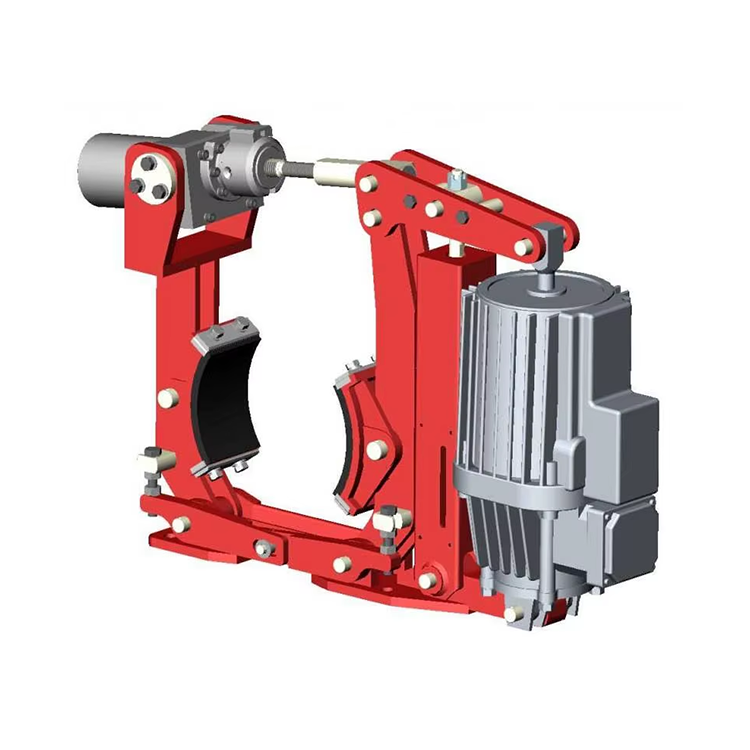

Drum Brake

The drum brake is a widely used mechanical braking device designed to provide reliable and effective deceleration in various industrial and automotive applications. It operates based on the principle of friction, where brake shoes press out...

The drum brake is a widely used mechanical braking device designed to provide reliable and effective deceleration in various industrial and automotive applications. It operates based on the principle of friction, where brake shoes press outward against a rotating drum attached to the wheel or shaft, generating resistance that slows or stops motion.

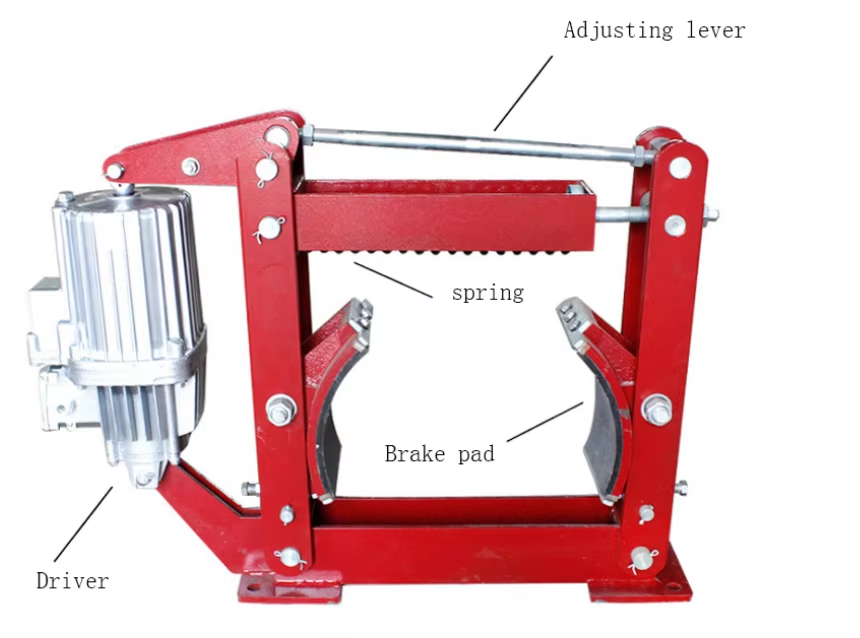

Constructed with high-strength cast iron or alloy steel, the drum brake features excellent wear resistance and heat dissipation properties. The internal brake shoes are typically lined with friction material that maintains consistent performance under heavy load and frequent braking cycles.

This type of brake is known for its stable braking force, low maintenance requirements, and long service life. It can be actuated mechanically, hydraulically, pneumatically, or electromagnetically, depending on the specific application requirements. Drum brakes are commonly used in cranes, hoists, conveyors, elevators, mining equipment, and large industrial machinery.

In applications where safety and load control are critical, the drum brake offers excellent holding torque and smooth operation. Optional features such as automatic wear adjustment, manual release levers, and dust protection are available to enhance performance and durability.

Drum brakes are especially suited for heavy-duty environments where high inertia loads must be controlled, making them a dependable and economical choice for both static and dynamic braking systems.