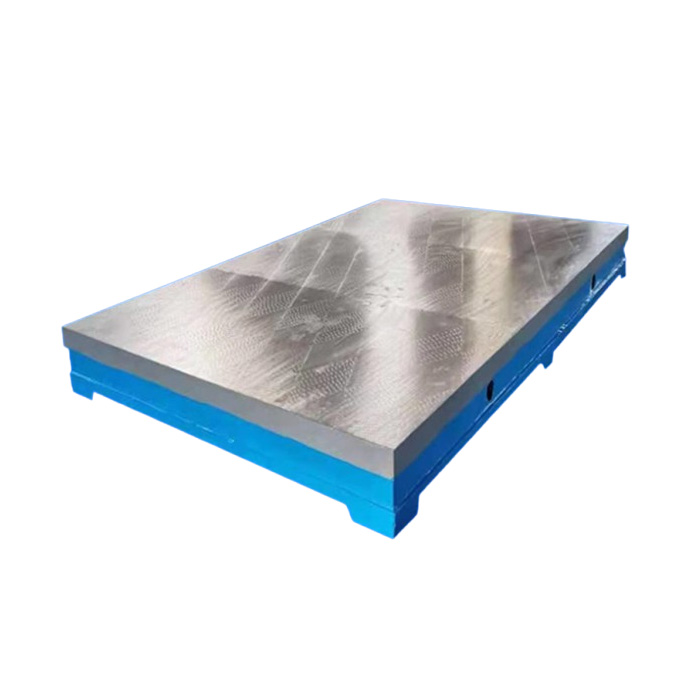

Cast Iron Surface Plate

Cast Iron Surface Plate – Detailed Product Description The cast iron surface plate is a precision measuring and inspection tool widely used in manufacturing, assembly, and quality control environments. It provides a stable, flat reference...

Cast Iron Surface Plate – Detailed Product Description

The cast iron surface plate is a precision measuring and inspection tool widely used in manufacturing, assembly, and quality control environments. It provides a stable, flat reference surface for accurate marking, layout, testing, and calibration of various components and instruments.

Material & Construction

Made from high-grade gray cast iron (commonly HT200–HT300), the surface plate undergoes a rigorous process of aging treatment and stress-relief annealing to ensure long-term dimensional stability and resistance to deformation. The microstructure of cast iron offers excellent wear resistance, vibration damping, and thermal stability, making it an ideal material for metrology applications.

Surface Finish & Accuracy

The working surface is hand-scraped or precision ground to meet international flatness standards such as DIN 876, GB/T 22095, or ASME B89.3.7M. Available in Grade 0, Grade 1, or Grade 2 accuracy, depending on the level of precision required, these plates provide high repeatability and reliable measurement conditions. The surface is finished with a finely textured matte to reduce light reflection and measurement errors.

Design Features

T-slot Options: Some cast iron plates come with T-slots for clamping fixtures or workpieces during machining or inspection.

Ribbed Underside: The bottom is reinforced with a ribbed structure to increase rigidity and reduce weight.

Mounting: Plates can be installed on adjustable leveling stands, support frames, or fixed directly onto a workbench.

Customization: Sizes, shapes (rectangular or square), and configurations can be customized based on client requirements.

Applications

Cast iron surface plates are essential tools in:

Machine tool alignment and installation

Precision part inspection

Calibration of measuring instruments

Layout and marking work in tool rooms

Surface flatness testing

Advantages

Excellent dimensional stability over time

High resistance to wear and corrosion

Cost-effective for large-scale and long-term use

Easy maintenance and reconditioning through re-scraping or re-grinding

Suitable for heavy-duty industrial environments

Typical Sizes

Standard sizes range from 300×300 mm up to 3000×6000 mm or larger, depending on application needs.

Conclusion

The cast iron surface plate is a fundamental tool for maintaining precision in manufacturing and inspection processes. Its robustness, longevity, and accuracy make it a preferred choice for engineers, machinists, and quality assurance professionals around the world.