Scraping Platform

Scraping Platform (Hand-Scraped Surface Plate) The scraping platform, also known as a hand-scraped surface plate, is a high-precision cast iron measuring tool used for inspection, layout, and precision assembly in machining and manufacturin...

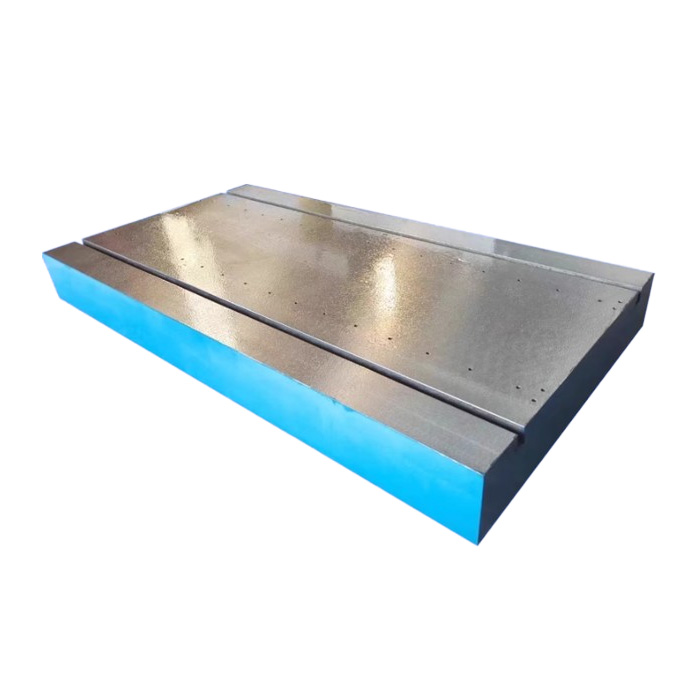

Scraping Platform (Hand-Scraped Surface Plate)

The scraping platform, also known as a hand-scraped surface plate, is a high-precision cast iron measuring tool used for inspection, layout, and precision assembly in machining and manufacturing. It is characterized by its meticulously hand-scraped working surface, ensuring excellent flatness, contact accuracy, and stability.

Product Features:

Material: High-quality gray cast iron HT200–HT300, with uniform structure and excellent wear resistance.

Surface Processing: The working surface is manually scraped by experienced technicians to achieve high-precision flatness and point contact requirements, ensuring superior measuring and fitting performance.

Flatness Grade: Available in Grade 1, Grade 2, and Grade 3 flatness according to GB/HT 22095-2008 standards.

Rigidity and Stability: Designed with reinforced ribbed structures to prevent deformation, offering long-term dimensional stability.

Applications:

Used as a reference surface for precision measurement and inspection.

Ideal for scribing, assembly of precision components, and positioning of workpieces.

Widely applied in mechanical manufacturing, aerospace, mold making, and tool production.

Advantages:

High dimensional accuracy and reliable performance.

Long service life with proper maintenance.

Suitable for both factory environments and precision workshops.

Optional Customization:

T-slots, holes, V-grooves, or mounting inserts available upon request.

Size and shape can be customized based on customer requirements.