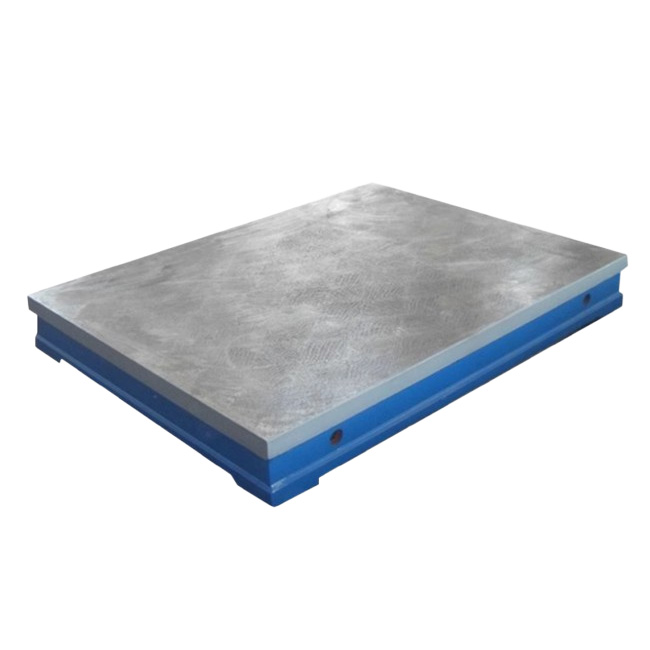

Fitter Marking-Out Plate

The fitter marking-out plate is a precision-ground cast iron surface designed for manual scribing, layout work, inspection, and part positioning in mechanical workshops. It provides a stable and flat reference base for skilled fitters durin...

The fitter marking-out plate is a precision-ground cast iron surface designed for manual scribing, layout work, inspection, and part positioning in mechanical workshops. It provides a stable and flat reference base for skilled fitters during metalworking, measurement, and fabrication tasks.

Material

Made from high-grade HT200–300 cast iron, the plate undergoes heat treatment, natural aging, or artificial annealing to eliminate internal stress and ensure long-term dimensional stability.

Key Features

High Surface Flatness

Manufactured to conform with DIN 876 or GB/T22095-2008 standards. Available in Grade 0, 1, or 2 flatness tolerances.Hand-Scraped or Machined Surface

The surface can be manually scraped for higher precision or finely machined, based on customer requirements.Reinforced Rib Structure

Designed with ribbed reinforcements underneath to resist deformation and vibration during use.Anti-Rust Treatment

Treated with protective coating to prevent rust during storage and use.

Applications

Manual scribing and layout marking of mechanical components

Workpiece positioning and measurement

Tool and die assembly

Visual inspection and testing

Use in fitter’s benches, repair shops, and tool rooms

Specifications

Flatness Grades: Grade 0 (high precision), Grade 1, Grade 2

Available Sizes: Customizable from 100×100 mm up to several meters in length and width

Surface Finish: Scraped, ground, or milled

Optional Add-ons: Leveling pads, lifting holes, or cast-in handles

Benefits

Stable and reliable reference surface

Enhances scribing precision and part alignment

Durable under repetitive use in tough working environments

Long service life with minimal maintenance

Conclusion

The cast iron fitter marking-out plate is an indispensable tool in mechanical fabrication and inspection tasks. Its high stability, precision, and rugged design make it a core component in tool rooms and manufacturing facilities worldwide.