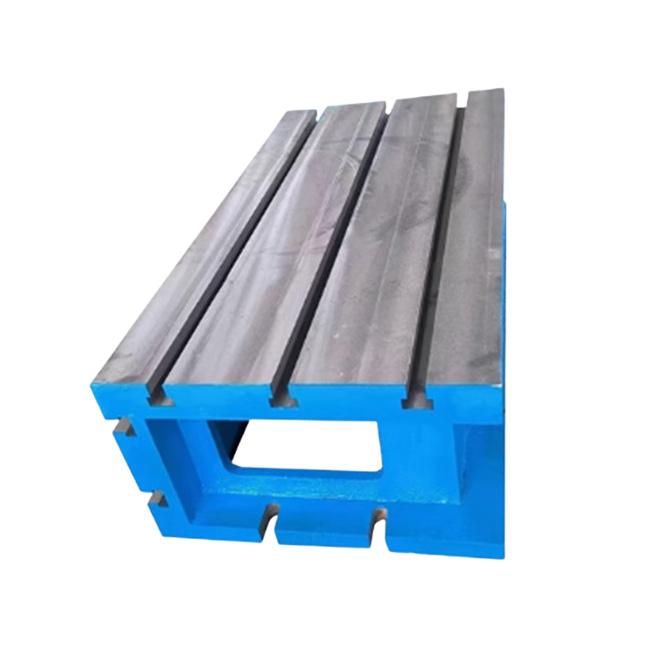

Cast Iron Square Box

The cast iron square box, also known as a cast iron angle plate or box angle plate, is a precision measuring and setup tool used in machining, inspection, marking, and assembly tasks. Made from high-grade cast iron, it provides accurate rig...

The cast iron square box, also known as a cast iron angle plate or box angle plate, is a precision measuring and setup tool used in machining, inspection, marking, and assembly tasks. Made from high-grade cast iron, it provides accurate right-angle surfaces for supporting and positioning workpieces during layout and inspection.

Key Features:

Material:

Made of high-strength cast iron HT200–HT300 with excellent wear resistance and dimensional stability.Precision Surfaces:

The working surfaces (outside and inside) are machined or scraped to achieve high accuracy, typically according to DIN or GB standards (Grade 1, Grade 2, or as specified).Structure:

Box-shaped hollow design with reinforced ribs, ensuring light weight while maintaining rigidity and resistance to deformation.Multiple Faces:

Provides multiple 90° right-angle surfaces, allowing flexible use in horizontal, vertical, or square setups.Customization:

Sizes, accuracy grades, and special features (such as threaded holes, slots, or lifting holes) can be customized on request.

Applications:

Precision machining alignment and inspection

Right-angle measurement and part squaring

Setup of vertical and horizontal machining operations

Support tool for marking and scribing operations

Fixture base in assembly and welding tasks

Advantages:

Ensures perpendicular alignment of components

Stable structure minimizes measurement error

Long service life with minimal maintenance

Corrosion-resistant surface treatment (optional)

Maintenance:

Store in a dry, dust-free environment

Apply rust-preventive oil after use

Avoid impacts or excessive loads on working surfaces

Regularly calibrate for precision assurance

Conclusion:

The Cast Iron Square Box is an essential tool in any machining or inspection workshop, delivering reliable 90° referencing for precision engineering tasks. Its durability, accuracy, and versatility make it ideal for both production and quality control environments.