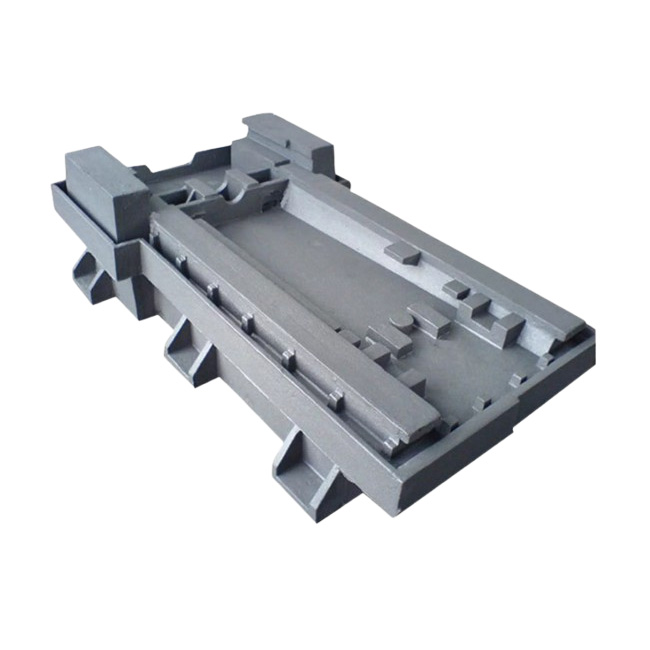

Cast Iron Machine Bed (Bed Castings)

The cast iron machine bed is a fundamental structural component used in CNC machines, lathes, milling machines, and other precision machinery. It is responsible for supporting all the major mechanical components and ensuring overall machine...

The cast iron machine bed is a fundamental structural component used in CNC machines, lathes, milling machines, and other precision machinery. It is responsible for supporting all the major mechanical components and ensuring overall machine rigidity, stability, and accuracy.

Material & Process:

Manufactured using high-quality HT200–HT300 or customized cast iron grades

Adopted advanced resin sand or lost foam casting technology

Aged with natural or artificial treatment to eliminate internal stress and avoid deformation

Precision machined to ensure dimensional accuracy and parallelism

Features:

High Rigidity & Stability: Excellent vibration damping performance ensures smooth machine operation and high machining accuracy

Superior Wear Resistance: Durable surface ideal for long-term industrial use

Customizable Dimensions: Available in various sizes and shapes according to customer drawings

Corrosion Resistant: Treated surfaces enhance lifespan under harsh working environments

Applications:

CNC Machining Centers

Horizontal and Vertical Lathes

Milling and Grinding Machines

Gantry and Boring Machines

Special-purpose machine tools requiring high precision support

Advantages:

Enhances machine tool accuracy and service life

Reduces vibration and heat deformation during operation

Optimized for high-load-bearing capacity and long-term performance

Optional Services:

Surface treatment (painting, priming, grinding)

CNC machining of mating surfaces

Assembly and quality inspection upon request