Universal Coupling

Universal Coupling (Universal Joint Coupling) A Universal Coupling, also known as a Universal Joint Coupling or U-joint, is a mechanical device used to transmit rotary motion and torque between two shafts that are not in a straight line. It...

Universal Coupling (Universal Joint Coupling)

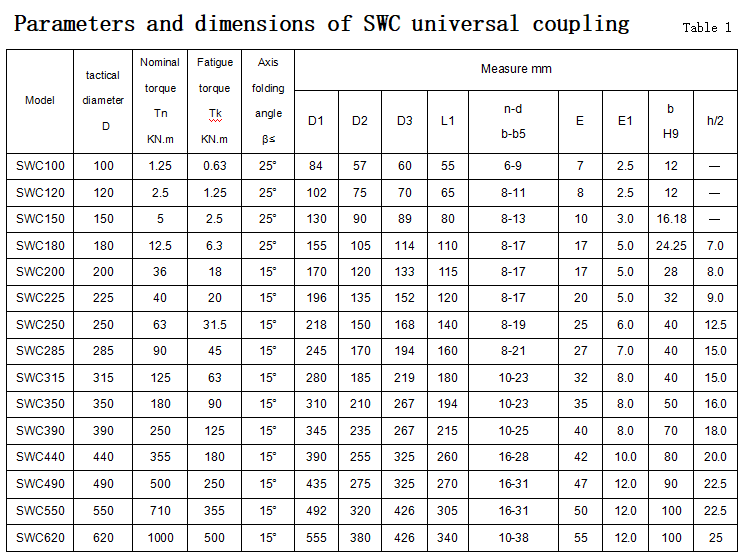

A Universal Coupling, also known as a Universal Joint Coupling or U-joint, is a mechanical device used to transmit rotary motion and torque between two shafts that are not in a straight line. It is especially suited for applications where shafts are misaligned or where the angle between the driving and driven shafts is variable during operation.

The core structure of a universal coupling consists of two yokes connected by a cross-shaped intermediate member known as a "spider" or "cross." This design allows for angular movement in multiple directions, providing flexibility and torque transmission even under substantial misalignment.

Universal couplings are highly effective in compensating for large angular displacements and are commonly used in long-distance shaft connections, particularly when the axes of the shafts intersect at an angle. They can accommodate misalignments in both horizontal and vertical planes and are capable of transmitting high torque at varying speeds.

These couplings are available in single-joint and double-joint configurations. A single universal joint allows angular movement but may cause speed fluctuations when transmitting at an angle. To counter this, double universal joints are used, which balance the angular velocities and provide smoother rotation.

Typical applications for universal couplings include automotive drive shafts, industrial machinery, rolling mills, heavy-duty lifting equipment, and marine propulsion systems. Their ability to handle heavy loads, absorb shock, and compensate for misalignment makes them indispensable in dynamic and demanding environments.

Universal couplings are made from high-strength alloy steels and are often heat-treated for durability and fatigue resistance. Depending on the specific application, they can be designed with or without lubrication, with sealed or open bearings, and with various connection methods such as flanges or keyways.

With their rugged design and exceptional flexibility, universal couplings are a reliable solution for transmitting mechanical power across challenging shaft arrangements.