FCL elastic sleeve pin coupling

The FCL Elastic Sleeve Pin Coupling is a flexible mechanical coupling designed to transmit torque between two shafts while effectively accommodating misalignment and absorbing shock loads. This coupling features two flanged hubs connected b...

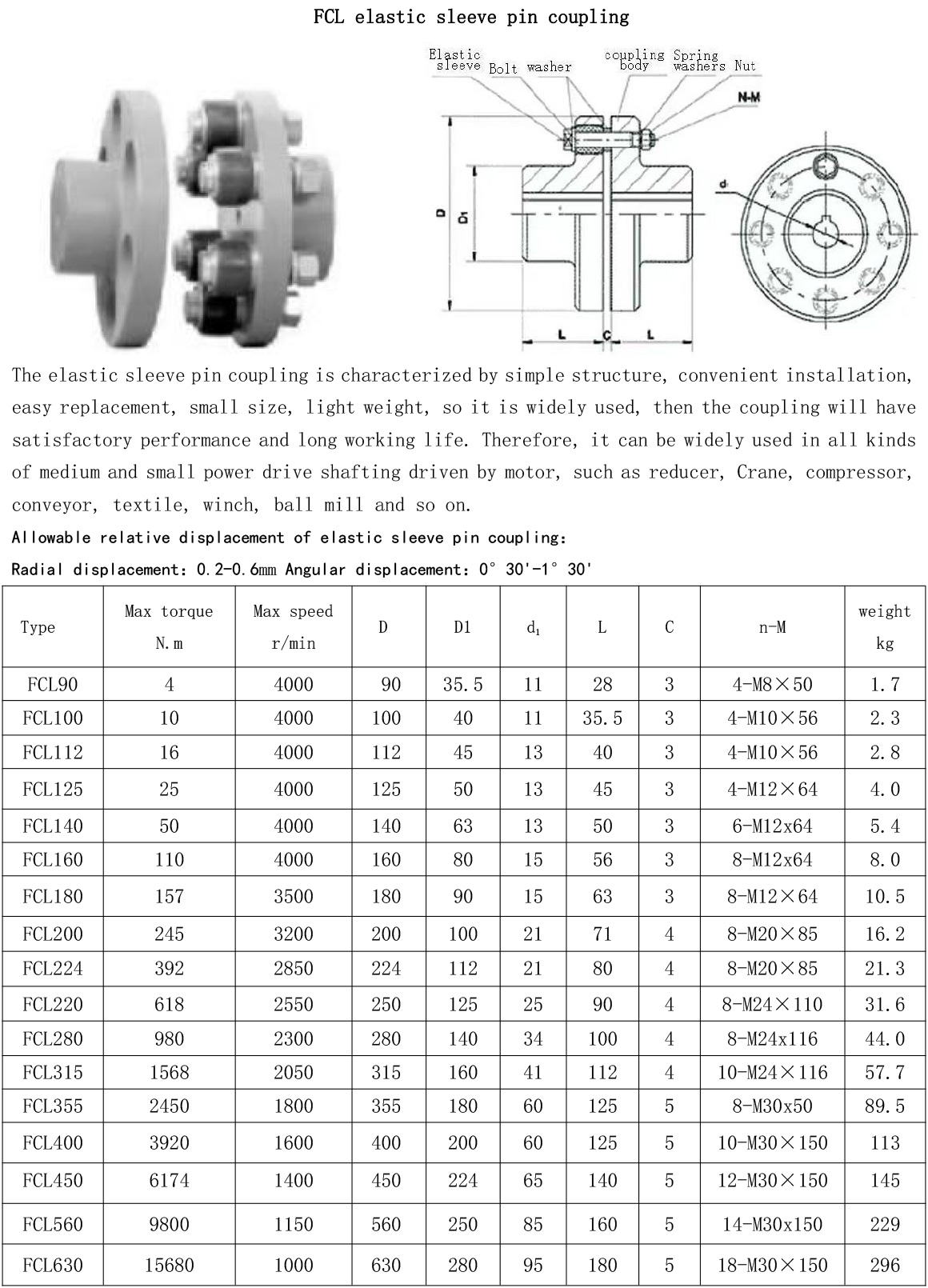

The FCL Elastic Sleeve Pin Coupling is a flexible mechanical coupling designed to transmit torque between two shafts while effectively accommodating misalignment and absorbing shock loads. This coupling features two flanged hubs connected by elastic pins and rubber or polyurethane sleeves, providing a resilient and reliable connection ideal for various industrial power transmission applications.

Constructed from high-strength cast steel or ductile iron, each hub has multiple holes around its flange for installing elastic pins. These pins are fitted with elastic sleeves that act as shock absorbers and vibration dampers, allowing the coupling to compensate for angular, axial, and radial misalignments. The elastic sleeves also reduce noise and protect connected equipment from torsional vibrations and sudden impact loads.

Key benefits of the FCL Elastic Sleeve Pin Coupling include its robust structure, simple design, and ease of installation and maintenance. It requires no lubrication, operates quietly, and offers excellent durability under demanding working conditions. This makes it well-suited for use in motors, pumps, compressors, conveyors, and other rotating machinery.

Commonly applied in industries such as mining, metallurgy, cement, chemical processing, and general manufacturing, the FCL coupling provides reliable, flexible torque transmission with enhanced shock absorption and misalignment tolerance.

Overall, the FCL Elastic Sleeve Pin Coupling is a cost-effective and durable solution for medium-duty mechanical drive systems, combining strength, flexibility, and vibration damping to extend equipment lifespan and improve operational stability.