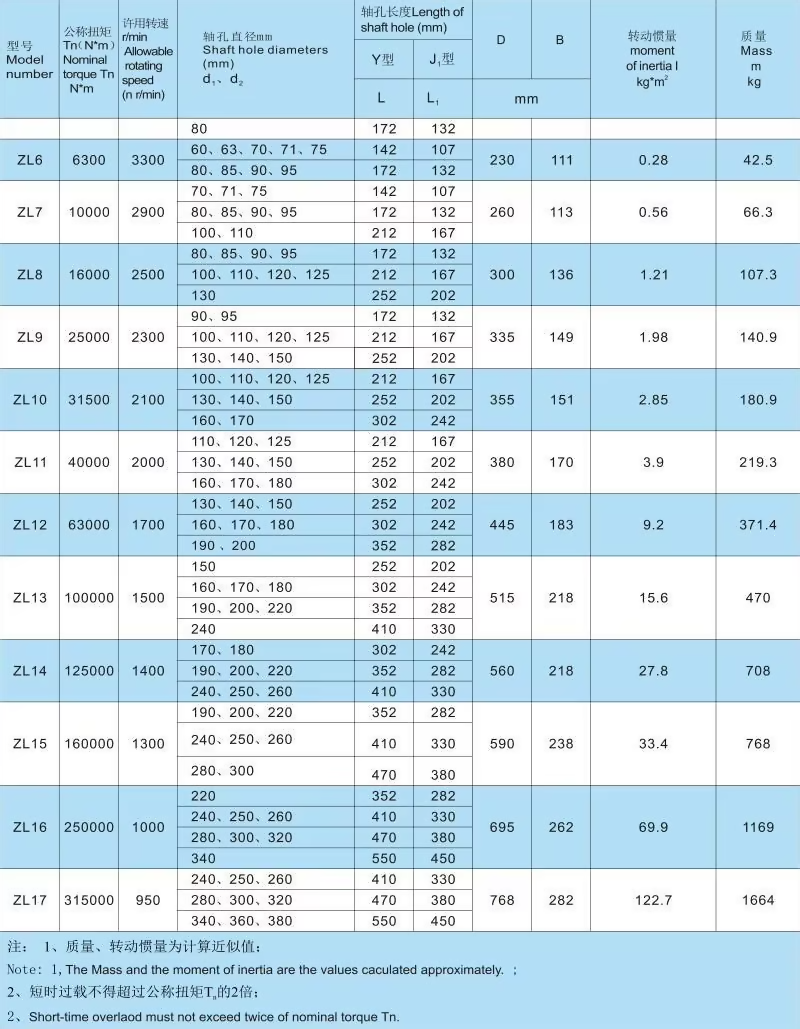

ZL gear coupling with elastic pins

The ZL gear coupling with elastic pins is a high-performance flexible coupling designed to connect two shafts while compensating for slight misalignments and dampening vibrations and shocks during torque transmission. It combines the advant...

The ZL gear coupling with elastic pins is a high-performance flexible coupling designed to connect two shafts while compensating for slight misalignments and dampening vibrations and shocks during torque transmission. It combines the advantages of traditional gear couplings with the added benefits of elastic damping elements.

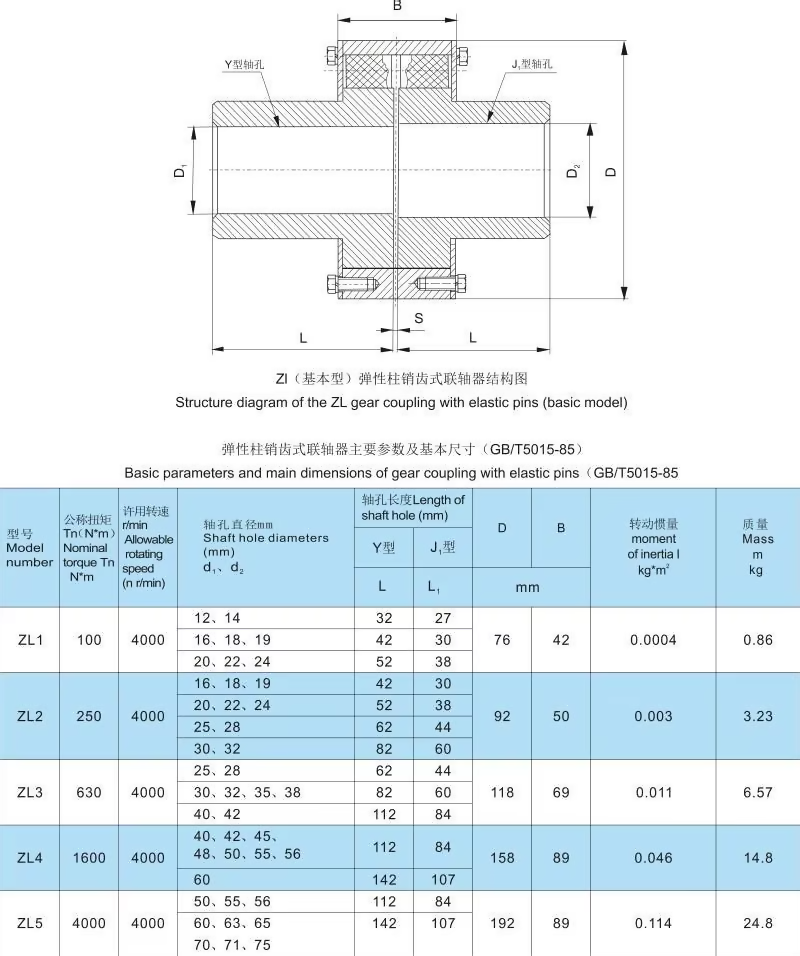

This coupling consists of two precisely machined steel gear hubs, each with external teeth, which mesh with internal teeth on a pair of flanged sleeves. The torque is transmitted through a set of elastic pins—typically made from high-strength rubber or polyurethane—that are installed through holes in the flanges of the sleeves. These elastic pins serve as flexible elements that absorb vibration and moderate impacts, providing additional protection to the connected equipment.

The ZL elastic pin gear coupling offers excellent angular and radial misalignment compensation, as well as limited axial displacement adaptability. Its structural design allows for high torque transmission capacity, while the elastic pins reduce noise, extend service life, and minimize wear on connected components. The damping performance of the pins is particularly beneficial in environments with frequent starts, stops, or load fluctuations.

Thanks to its robust structure and reliable performance, the ZL gear coupling with elastic pins is widely used in heavy-duty industrial machinery, such as metallurgy equipment, mining conveyors, cranes, fans, compressors, and other high-torque transmission systems.

In addition, the coupling is easy to assemble and disassemble, making it convenient for maintenance and reducing downtime. Its modular design also allows for easy replacement of the elastic pins without needing to disassemble the entire coupling.

Overall, the ZL gear coupling with elastic pins delivers stable, efficient, and vibration-resistant shaft connection, making it a practical and durable solution for a wide range of industrial power transmission applications.