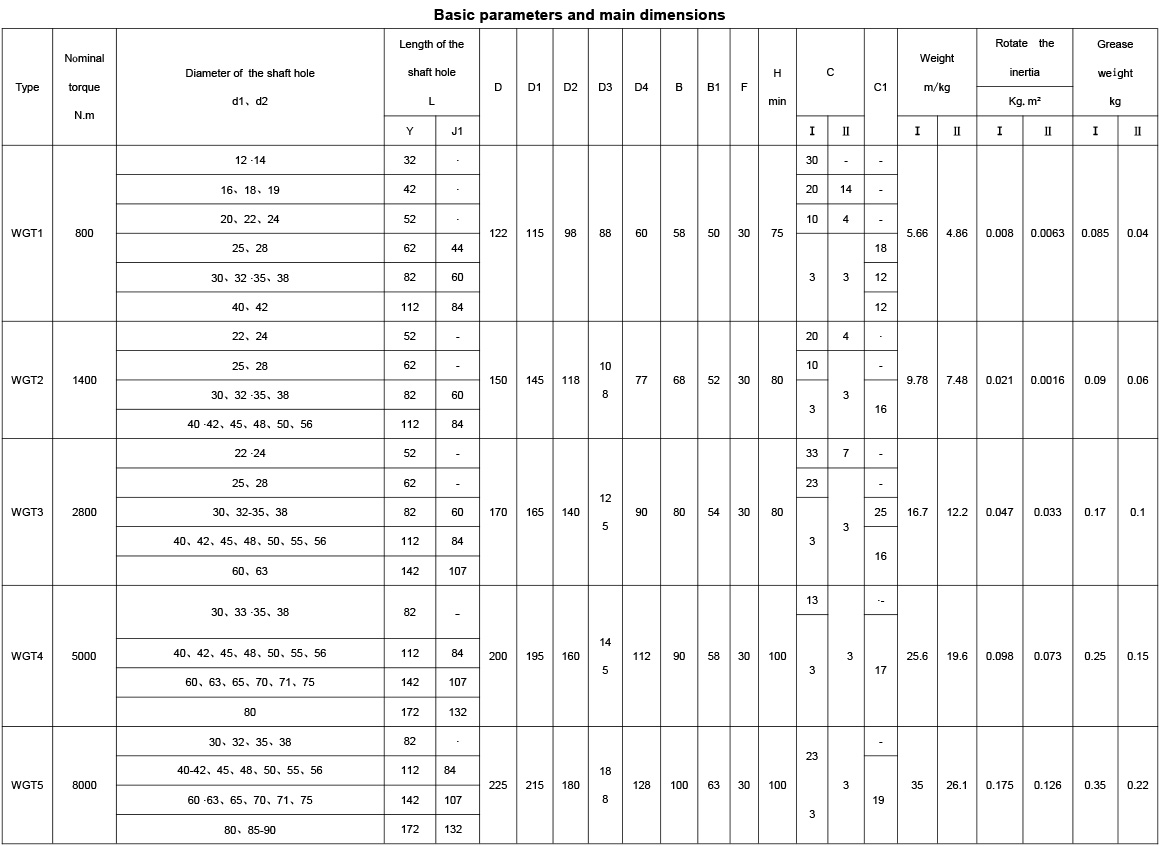

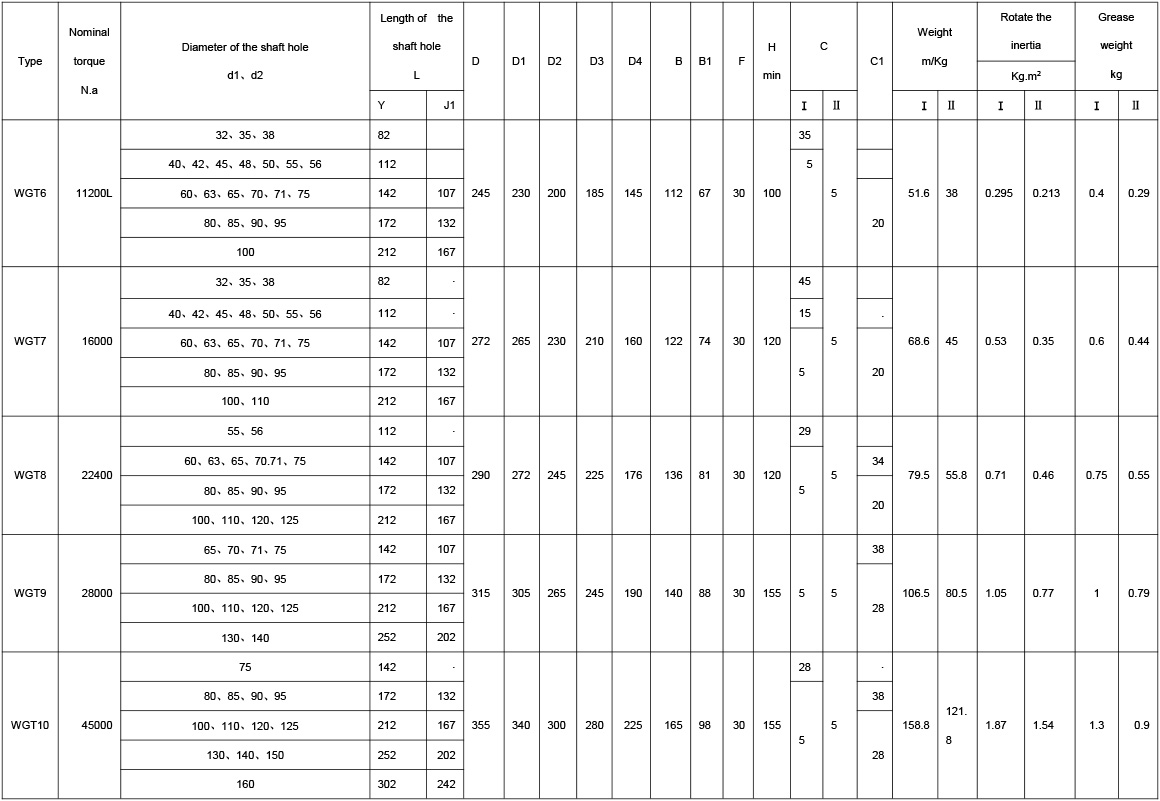

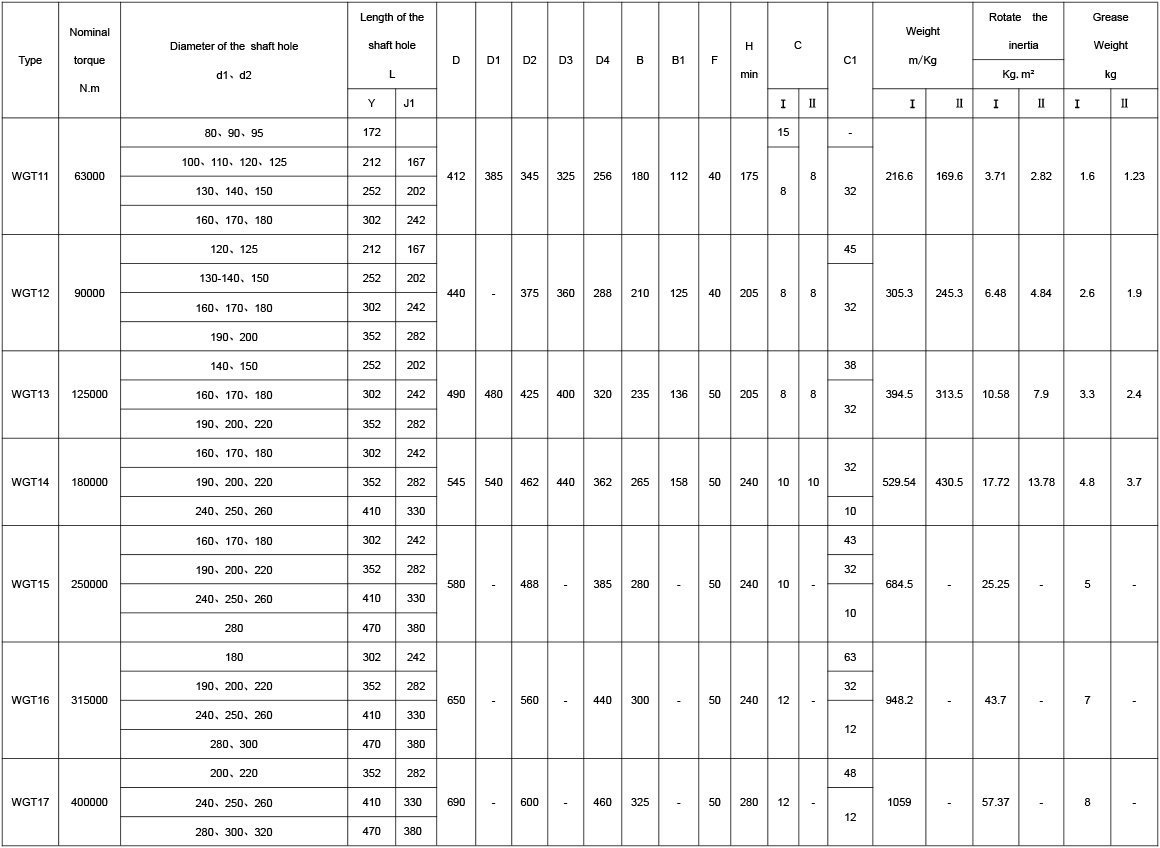

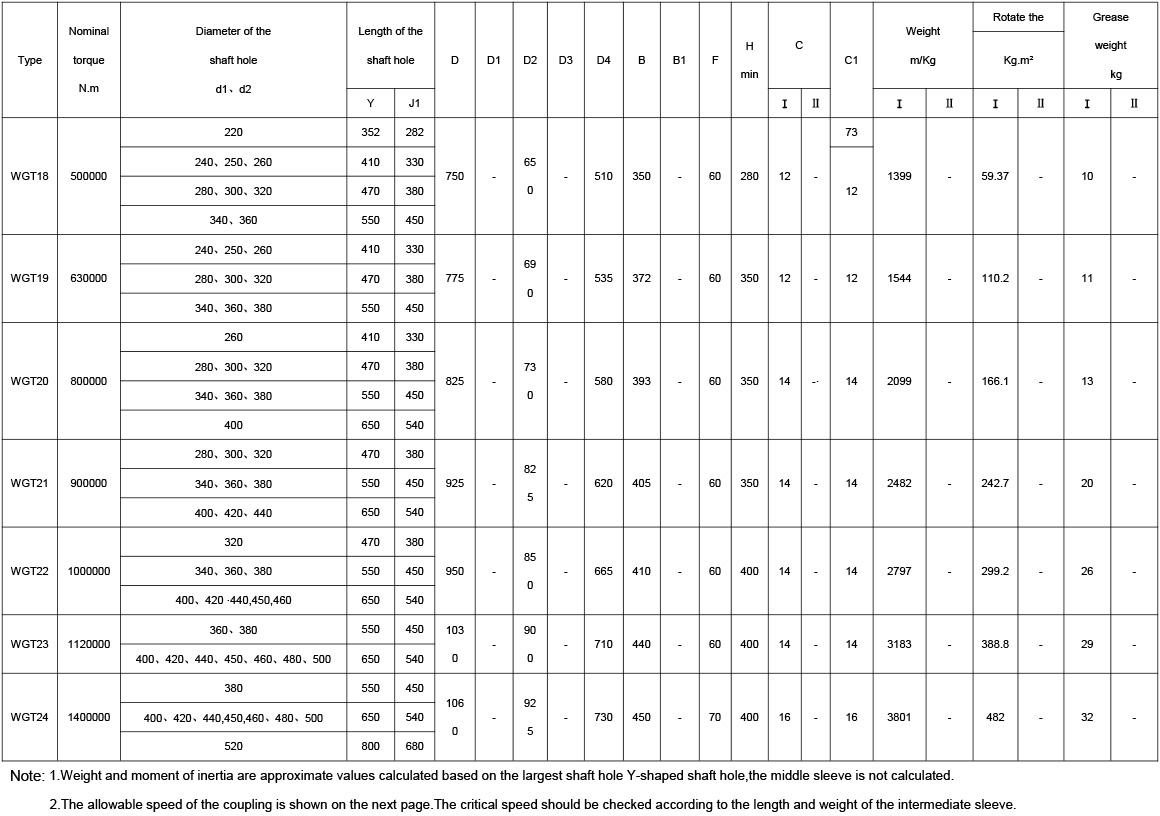

WGT Type Drum Gear Coupling with Intermediate Sleeve

The WGT Type Drum Gear Coupling is a high-performance flexible coupling designed with an intermediate sleeve, allowing for longer axial distances between connected shafts. It is particularly suitable for machinery requiring shaft-to-shaft c...

The WGT Type Drum Gear Coupling is a high-performance flexible coupling designed with an intermediate sleeve, allowing for longer axial distances between connected shafts. It is particularly suitable for machinery requiring shaft-to-shaft connections across extended spans while still ensuring high torque transmission, misalignment compensation, and durability under heavy loads.

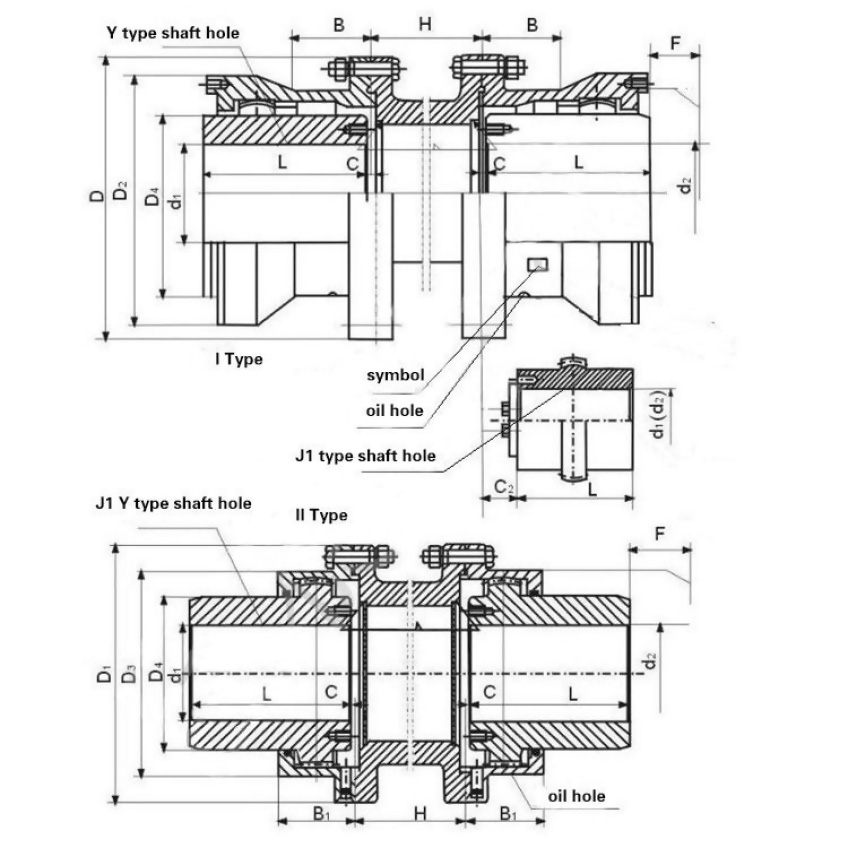

The coupling consists of two hubs with crowned external gear teeth, two internal gear sleeves, and a rigid intermediate tube (spacer). The drum-shaped gear design allows for better contact and alignment, reducing stress concentrations and improving service life. The intermediate sleeve makes this coupling ideal for applications where space constraints or alignment conditions require separation between the driving and driven ends.

Key Features:

Extended shaft distance capability

The intermediate sleeve allows for longer axial spans between connected equipment, ideal for bridge-mounted or overhanging installations.Drum-shaped gear teeth design

Provides enhanced angular misalignment capacity (typically up to ±1.5°), reducing edge loading and increasing load-carrying ability.High torque transmission

Built to handle large torsional forces in heavy-duty industrial applications.Accommodates misalignment

Effectively compensates for angular, axial, and small radial misalignment between shafts.Robust and durable structure

Manufactured from high-strength steel with heat-treated, precision-machined gear teeth for excellent wear resistance and extended service life.Modular and service-friendly

The coupling’s bolt-connected flanges and sleeve structure make it easy to install, inspect, and maintain.

Typical Applications:

The WGT Gear Coupling with Intermediate Sleeve is widely used in:

Large pump and fan systems

Conveyors and material handling lines

Steel mill and rolling equipment

Compressors and blowers

Applications requiring precise shaft alignment over distance

Operating Conditions:

Ambient temperature: –20°C to +80°C

Suitable for forward and reverse operation

Lubricated with grease or oil depending on application requirements

Designed for horizontal installations (can be customized for vertical use)

Capable of long-term operation in demanding environments

The WGT Type Drum Gear Coupling with Intermediate Sleeve is a reliable solution for industrial systems requiring both flexibility and shaft extension. Its proven design, high load capacity, and ease of maintenance make it an excellent choice for high-performance, long-span coupling applications.