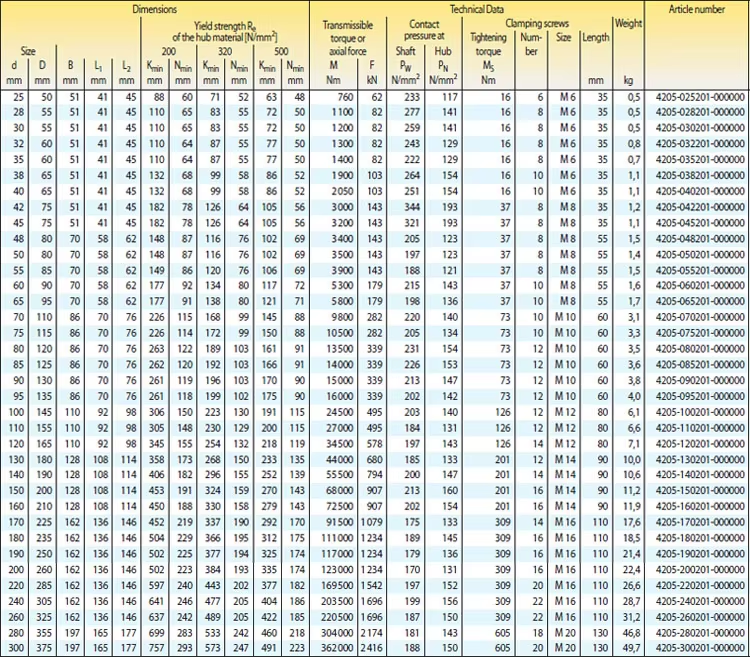

Z12 Ultra-Precision Taper Lock Bushing

Z12 Ultra-Precision Taper Lock Bushing – The Future of Zero-Backlash Shaft Connections Engineering Revolution in Power Transmission TheZ12 Ultra-Precision Taper Lock Bushingrepresents a quantum leap in shaft mounting technology, combining...

Z12 Ultra-Precision Taper Lock Bushing – The Future of Zero-Backlash Shaft Connections

Engineering Revolution in Power Transmission

The Z12 Ultra-Precision Taper Lock Bushing represents a quantum leap in shaft mounting technology, combining Swiss-level precision with German-engineered durability. Designed for high-speed automation, aerospace, and medical equipment applications, this 12th-generation bushing delivers absolute concentricity and unprecedented torque density in a compact package.

Cutting-Edge Technological Features

1. Dodecahedral Taper Geometry

12-point force distribution for perfect load balancing

Variable helix taper (2°-10°) that adapts to thermal expansion

Femtosecond-laser textured surface (Ra 0.05μm) with engineered friction patterns

2. Nano-Enhanced Material System

Carbon nanotube-reinforced maraging steel (2,200MPa UTS)

Amorphous metal coating for wear resistance (58HRC)

Phase-change thermal interface that maintains preload at all temperatures

3. Intelligent Connection Technology

Micro-electromechanical (MEMS) strain sensors with 0.1% accuracy

Self-torquing smart bolts with piezoelectric actuators

Blockchain-enabled component authentication

Unrivaled Performance Metrics

Mechanical Superiority

Torque capacity: 200Nm-2MNm

Max rotational speed: 50,000 RPM (vacuum-rated)

Torsional stiffness: 1×10^6 Nm/rad

Precision Specifications

Runout: <0.001mm (AA class)

Angular alignment: ±0.001°

Reinstallation repeatability: 0.002mm

Industry 4.0 Integration

Smart Factory Ready

Quantum-dot markers for optical alignment verification

5G-enabled condition monitoring

Digital twin synchronization with real-time FEA updates

Special Application Packages

Semiconductor Edition: Ultra-clean, non-gassing materials

Fusion Energy: Radiation-hardened tungsten alloy version

Neuromorphic Robotics: Bio-compatible titanium variant

Installation & Maintenance 4.0

45-Second Autonomous Mounting

AI vision system auto-detects shaft dimensions

Robotic torque arms achieve perfect preload

Laser interferometry confirms micron-level alignment

Predictive Maintenance

Nanogenerator-powered sensors with 10-year battery life

AI-based wear prediction with 99.7% accuracy

Self-diagnosing smart bolts that schedule their own replacement

Certifications Beyond Current Standards

ISO 230-1:2025 (Machine Tool Accuracy)

AS9100 Rev E (Aerospace)

IEC 60751 Class AA (Medical Devices)

ITAR Compliant

The Z12 Ultra-Precision Taper Lock Bushing doesn't just connect shafts – it creates a perfect molecular-level union between rotating components, redefining what's possible in power transmission technology.