Omega Coupling

The Omega coupling is a high-performance, flexible elastomeric coupling designed to accommodate misalignment, dampen vibration, and absorb shock loads in a wide range of industrial applications. Its unique design features a split-in-half po...

The Omega coupling is a high-performance, flexible elastomeric coupling designed to accommodate misalignment, dampen vibration, and absorb shock loads in a wide range of industrial applications. Its unique design features a split-in-half polyurethane elastomer element shaped like the Greek letter "Ω" (Omega), which provides excellent flexibility and torsional damping while maintaining high torque transmission capability.

The Omega coupling consists of two metallic hubs and a removable elastomeric element that allows for easy installation and replacement without disturbing the connected equipment. This design ensures minimal downtime during maintenance and reduces overall operational costs.

One of the key advantages of the Omega coupling is its ability to compensate for angular, axial, and parallel misalignment, thereby extending the lifespan of connected machinery. It also provides a fail-safe design, which means limited torque transmission can continue even if the elastomer fails, offering enhanced safety and reliability.

Omega couplings are non-lubricated, which eliminates the need for routine maintenance and makes them suitable for clean environments. They are widely used in pumps, compressors, conveyors, blowers, fans, and other rotating equipment in industries such as power generation, mining, chemical processing, and water treatment.

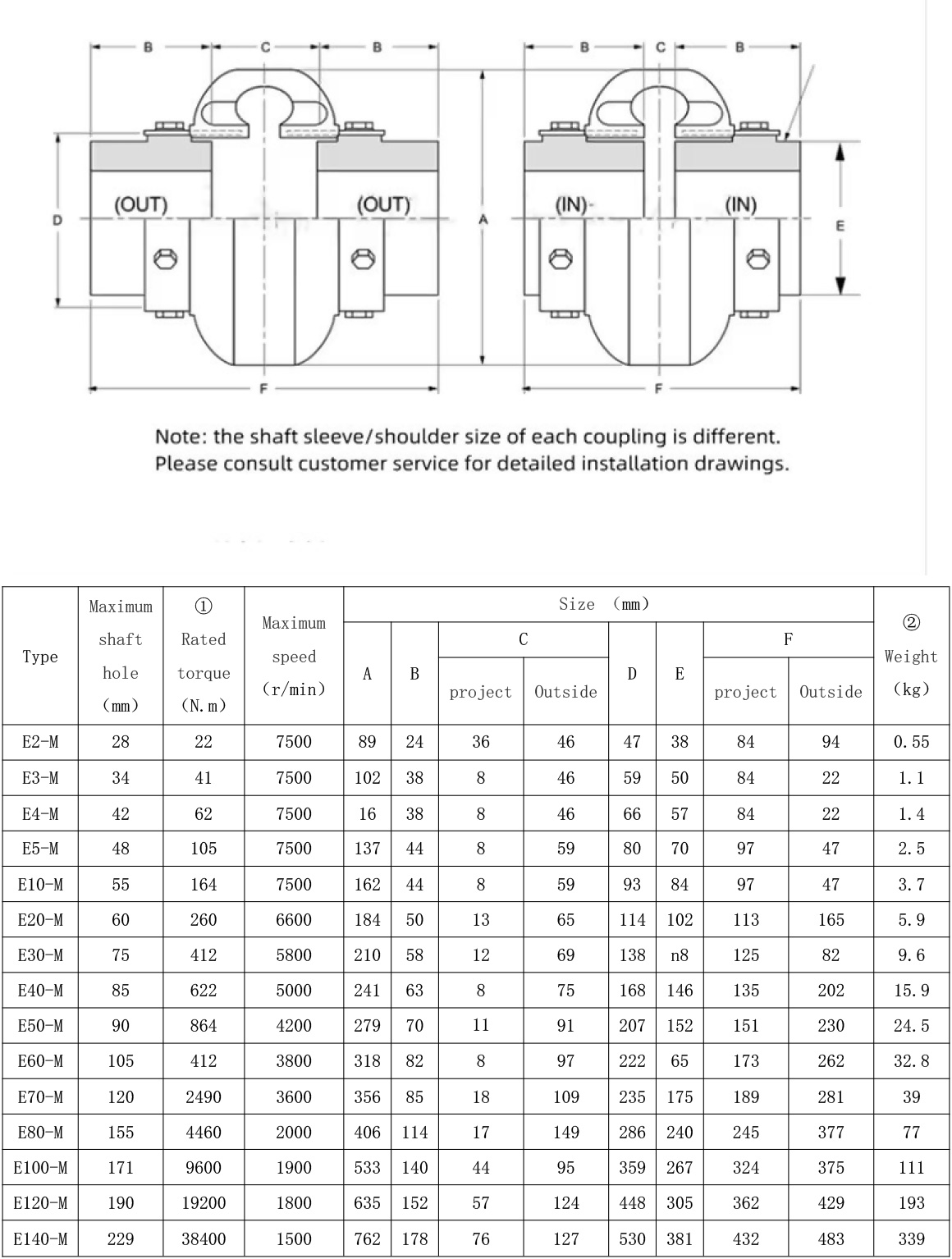

Available in a wide range of sizes and materials, the Omega coupling can be customized to meet various torque and speed requirements, making it a versatile solution for demanding mechanical power transmission applications.