GY type flange coupling

GY Type Flange Coupling – Heavy-Duty Rigid Shaft Connection System Product Overview TheGY Type Flange Couplingis a high-performance rigid coupling designed for permanent shaft-to-shaft connections requiring absolute torque transmission wi...

GY Type Flange Coupling – Heavy-Duty Rigid Shaft Connection System

Product Overview

The GY Type Flange Coupling is a high-performance rigid coupling designed for permanent shaft-to-shaft connections requiring absolute torque transmission without angular flexibility. Engineered for critical power transmission applications, this forged steel flange coupling delivers unmatched reliability in turbine, generator, and heavy industrial applications where shaft alignment must be maintained precisely.

Key Features & Benefits

1. Monolithic Forged Construction

Single-piece forged steel (ASTM A105/A350) for maximum structural integrity

Precision-machined mating surfaces with Ra 0.8μm finish

Dyno-balanced to G1.0 grade at operating speeds

2. Torque-Optimized Design

Interlocking rabbet fit ensures perfect concentricity

High-tensile alloy bolts (ISO 898-1 Class 10.9) with Nord-Lock washers

Shear ring option for overload protection

3. Specialized Surface Treatments

Black oxide/phosphate coating standard

Optional coatings:

HVOF tungsten carbide for abrasive environments

Electroless nickel for chemical resistance

Cryogenic-treated versions for stability

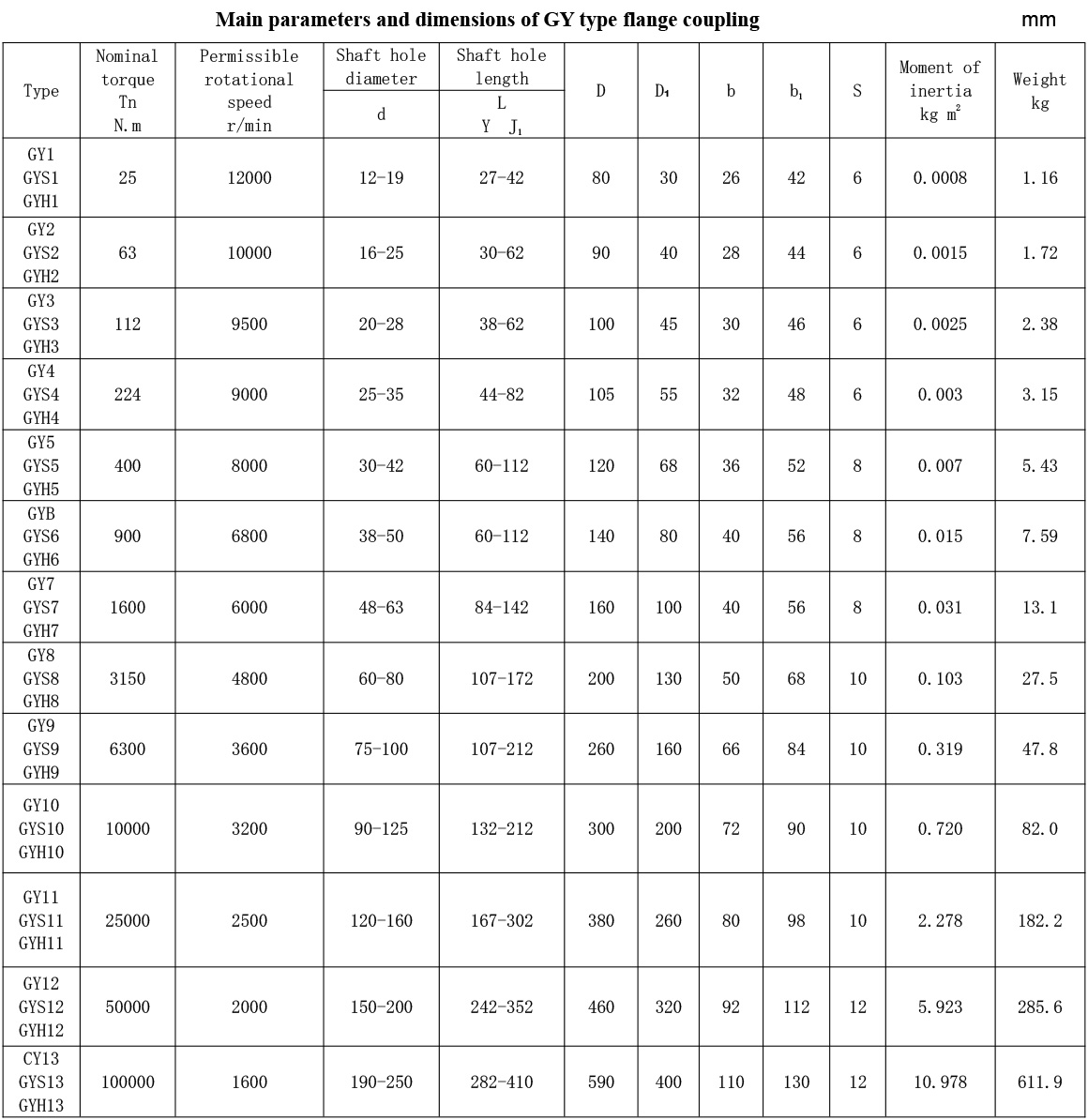

Technical Specifications

Mechanical Performance

Torque capacity: 5,000Nm–5MNm

Max speed: 3,600 RPM (higher speeds with custom balancing)

Bore tolerance: H7/h6 (P6 available)

Environmental Durability

Temperature range: -60°C to +400°C

Corrosion resistance: 1,000hr salt spray (ASTM B117)

Pressure-rated versions: ANSI 900# flange standard

Industry-Specific Solutions

Power Generation

API 671 compliant for turbine-generator sets

Keyway and keyless hydraulic fit versions

Marine Propulsion

DNV-GL/ABS/LR certified

Cathodic protection compatible

Mining & Minerals

X-ray inspected weld necks

Abrasion-resistant hardfacing

Installation & Maintenance

Precision Alignment Features

Laser-etched alignment marks

Dial indicator mounting grooves

Tapered alignment pins (DIN 6325)

Maintenance Advantages

Permanent lubrication (lubrication port options)

Bolt stress monitoring system available

20+ year design life

Certifications:

ASME B16.5 (Flange dimensions)

PED 2014/68/EU

NACE MR0175 for sour service

The GY Type Flange Coupling represents the pinnacle of permanent, high-power shaft connections – where absolute reliability cannot be compromised.