Tapping Machine Worktable

The tapping machine worktable is a precision-engineered base platform designed specifically to support tapping operations with enhanced accuracy, stability, and efficiency. It plays a crucial role in providing a secure and level surface for...

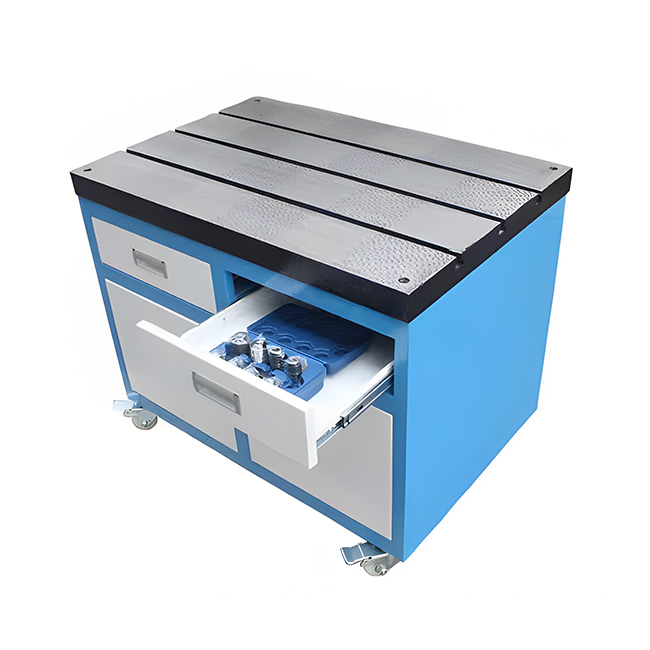

The tapping machine worktable is a precision-engineered base platform designed specifically to support tapping operations with enhanced accuracy, stability, and efficiency. It plays a crucial role in providing a secure and level surface for mounting tapping machines and workpieces, making it indispensable in metalworking and manufacturing environments.

Constructed from high-quality cast iron, the worktable is heat-treated and stress-relieved to eliminate internal stresses and prevent long-term deformation. The robust structure ensures excellent vibration damping, which is essential for maintaining tapping accuracy and protecting both the machine and the tooling.

The surface of the worktable is meticulously machined or hand-scraped to achieve high flatness and smoothness, meeting industry standards such as DIN 876 or GB/T. It often features T-slots or precision-drilled holes that allow for easy installation of tapping machines, fixtures, or work-holding devices. This design enables quick setup and consistent positioning during repetitive tapping operations.

Key Features:

Made from HT200/HT250 cast iron for superior rigidity and durability

High flatness accuracy, ensuring precision in tapping operations

T-slots or threaded holes available for flexible mounting options

Excellent shock absorption reduces machine wear and enhances thread quality

Suitable for both manual and automatic tapping machines

Corrosion-resistant surface treatment for long-term use in workshop environments

Applications:

This worktable is widely used in machining centers, tapping stations, mold workshops, and assembly lines. It supports a variety of applications including internal threading, blind hole tapping, and continuous batch tapping of components made from steel, aluminum, and other metals.

Available in various sizes and configurations, the tapping machine worktable can be customized according to customer specifications. Whether for heavy-duty industrial use or light workshop applications, it provides a reliable foundation for precise and efficient tapping processes.