The cast iron bench worktable is a robust and precision-machined working platform designed to support various manual and semi-automatic metalworking tasks, especially in fitting, assembly, and inspection operations. Built to withstand high-impact forces and daily industrial wear, it is a staple fixture in machine shops, assembly lines, and maintenance workshops.

Material & Structure

This worktable is manufactured from HT200 or HT250 high-strength gray cast iron, offering outstanding stability, rigidity, and vibration damping performance. The cast structure undergoes natural aging or artificial stress relief to eliminate internal stresses and prevent warping over time.

The table surface is finely machined or hand-scraped to meet precision standards such as DIN 876 / GB/T 22095, ensuring a flat, smooth, and wear-resistant platform. Reinforcement ribs beneath the tabletop improve load-bearing capacity and minimize deformation under heavy tools or parts.

Design Features

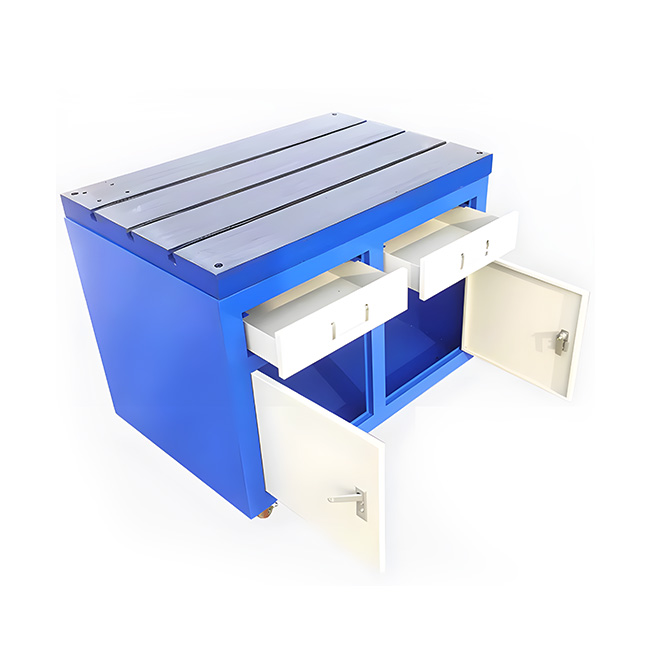

Flat Working Surface: Precision-machined surface ideal for fitting, layout marking, inspection, and assembly tasks.

Durable Cast Iron Body: Offers long service life with excellent resistance to mechanical wear and heat.

Reinforced Rib Structure: Ensures excellent rigidity and weight-bearing capability.

Edge Chamfering: Rounded or chamfered edges for safety and operator comfort.

Optional Drawers or Storage Units: Some models include tool drawers or cabinets for integrated storage and workflow efficiency.

Customizable Sizes: Available in a wide range of dimensions and configurations according to user requirements.

Typical Applications

Manual fitting and hand tooling operations

Assembly of mechanical components

Measurement and marking work in tool rooms

Maintenance and repair stations

Inspection and testing of parts or fixtures

Advantages

High load-bearing capacity

Exceptional dimensional stability over time

Resistant to cutting fluids, oil, and mechanical abrasion

Long lifespan with minimal maintenance

Adaptable to various workshop environments